Please note that by clicking on the below link you will download an extract of the Initial Report, which is to be read in light of the Initial Report, the Glossary of terms and Acknowledgements and Legal.

Click below to download the full Initial Report.

Click below to download Glossary of Terms

Click below to download Acknowledgements and Legal.

The Industry Component of our Initial Report contains an overview of the Egg Supply Chain and Egg Supply Industry in South Africa and background to contextualise certain important aspects of how it operates and its impact on different stakeholders.

As one of South Africa’s most important agricultural sub-sectors worth billions of rands, it is not surprising that the Poultry Industry, including the Egg Industry is very well organised. SAPA is the body representing the interests of the industry and has been around for over 80 years. The Egg Industry has a value of ZAR 11.44 billion with a 3.1% share of total agriculture production in South Africa making this industry a key space of engagement. The Egg Industry consists of both formal and informal markets.

While there are many different role-players involved in the Egg Industry, there are several major players with integrated structures, making them very powerful entities with a lot of influence. For example, Nulaid, the egg-layer division of Quantum Foods, is the largest egg producer in South Africa and the only national producer. Emerging egg producers constitute only 1.0 % of the industry.

After embarking on this Project, it became apparent that it was necessary to try to understand and contextualise the Egg Industry as well as the relevant role-players. This Section contains some initial information about the Egg Industry largely sourced from SAPA and DALRRD, as well as a Stakeholder Mapping process that ALRSA undertook as part of the Project. The Stakeholder Mapping process is discussed further in Section IV.

Challenges identified by SAPA in the recent profile include:

“bird welfare legislation, plant-based alternatives to eggs and broiler meat, regulations governing the use of antibiotics in production, and environmental sustainability issues”.

The Research Component as contained in Section III and the Stakeholder Component in Section IV should be considered against the background of the Industry Component.

POULTRY INDUSTRY CLASSIFICATIONS

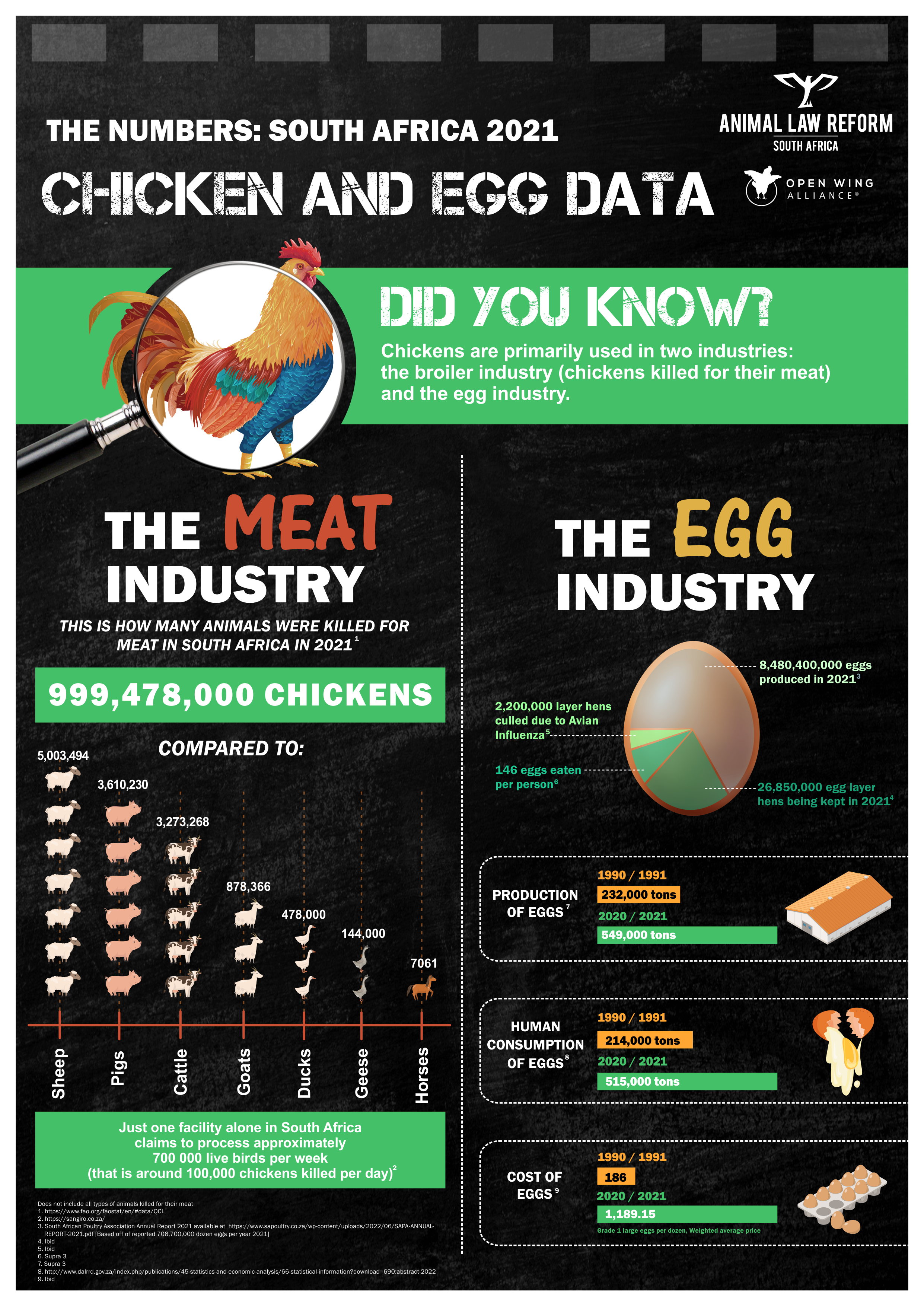

Chickens and other birds in the Poultry Industry are predominantly used in one of two ways:

The broiler industry is not the focus of this Initial Report, other than for comparative or contextual matters, as the focus is the Egg Industry. However, many of the same major role-players are active in both the Egg Industry and broiler industry. In South Africa, approximately 74% of the birds are killed for their meat, while 26% are used as Layers.

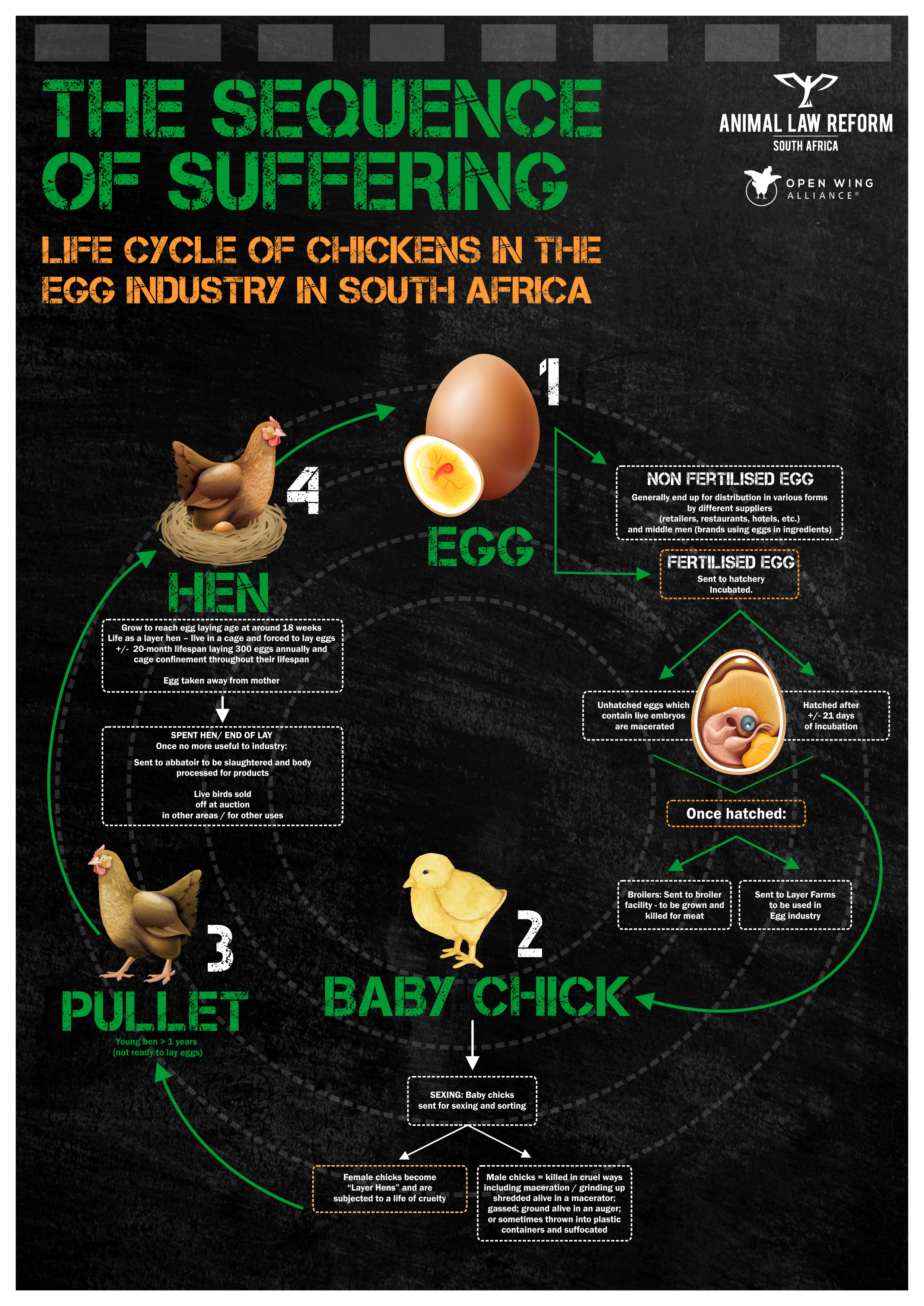

LIFE CYCLE AND TERMS

A summarised understanding of different stages of the life cycle of and activities relating to chickens in the Egg Industry is included below:

EGG:

CHICKS / PULLETS:

[Hatcheries – Hatched]

SEXING:

[Sent for sexing and sorting]

PULLETS: Young hens less than 1 year old who are not yet physically mature enough to lay eggs. Once they reach a certain age (generally 52 weeks or 1 year), they become Laying Hens.

EGG LAYERS / LAYING HENS: These birds grow to reach egg laying age at around 21 weeks. They live their short lives as Layer Hens – in cages and forced to lay eggs. Their eggs are consistently taken away from them. They generally have a +/- 20-month lifespan laying 300 eggs annually and cage confinement throughout their lifespan until they become are considered to be “spent”.

SPENT HENS / END OF LAY: Once Layer Hens are of no more useful to the Egg Industry / their productivity drops to unprofitable levels:

TYPES OF PRODUCTS

Within the Egg Supply Chain various products (in addition to whole eggs) are produced, including but not limited to powdered and liquid eggs. The Initial Report and the Project focuses predominantly on whole eggs including those sold and utilised for sale and consumption by the public. However, other forms of eggs are important and must be considered for future research.

TYPES OF EGGS

GRADE / QUALITY

Eggs in South Africa are classified according to grades and size. Eggs that do not comply with the standards for grading are not presented for sale.

Agriculture and Agri-Food regulations define three quality grades that apply to eggs for sale to customers, based on their appearance, condition, and quality of the egg’s shell, egg white, and yolk. These are:

SIZE

Only Grade A eggs are sized according to the weight of each egg:

The multitude of egg uses in the Egg Industry and profit produced entails a range of actors involved at the various stages in the Egg Supply Chain. Those involved in egg production use a range of production systems.

According to SAPA, the Poultry Industry is the largest single contributor to the agricultural sector in South Africa. In 2021, approximately 16.6% of the total agricultural gross value and 39.9% of animal product gross value stemmed from poultry production. The 16.6% contribution from poultry products breaks down into 13.6% from poultry meat and 3.05% from eggs. The gross value of egg production for 2021 was recorded at R11.44 billion (+ 0.9 %).

The Egg Industry’s nearest competitor, the beef industry, contributed 11.5% to turnover of all agricultural production and 27.5 % of animal products. The total gross value of animal products was R156.51 billion and the total gross value of agricultural products was R374.81 billion in 2021. Total animal products contributed 41.8 % to the gross value of total agricultural products.

There is a significant number of producers spread across most provinces. About 50% or more of the eggs produced are channelled through the formal markets, with 40% to 50% being sold on the informal markets.

South Africa is required to meet standards for the export of its products outside of the country. Imports in South Africa are largely exchange rate driven while exports are mainly affected by sanitary rules that the European Union (“EU”), United States of America (“USA”), and others apply.

It is estimated that the Egg Industry provides direct and indirect employment to over 110 000 people; is the second largest consumer of maize in the country; and supports many peripheral businesses (including the feed industry) and those downstream in the value chain.

According to SAPA, eggs remain the cheapest animal protein available to consumers, with per capita consumption of 159 eggs per person in 2020.

“Externalities” are not factored into these calculations around price. An externality is a side effect or consequence of an industrial or commercial activity that affects other parties without this being reflected in the cost of the goods or services involved, for example the environmental costs.

Corporate Accountability and the Egg Industry in South Africa

Updated in February 2025 (v3) with minor amendments

[*Note originally published in August 2023 (v1) and

amended in September 2024 (v2)]

Environmental and Consumer Rights in the Egg Industry in South Africa

Updated in February 2025 (v2) with minor amendments

[*Note originally published in September 2024 (v1)]